Simple structure, high reliability, and long service life

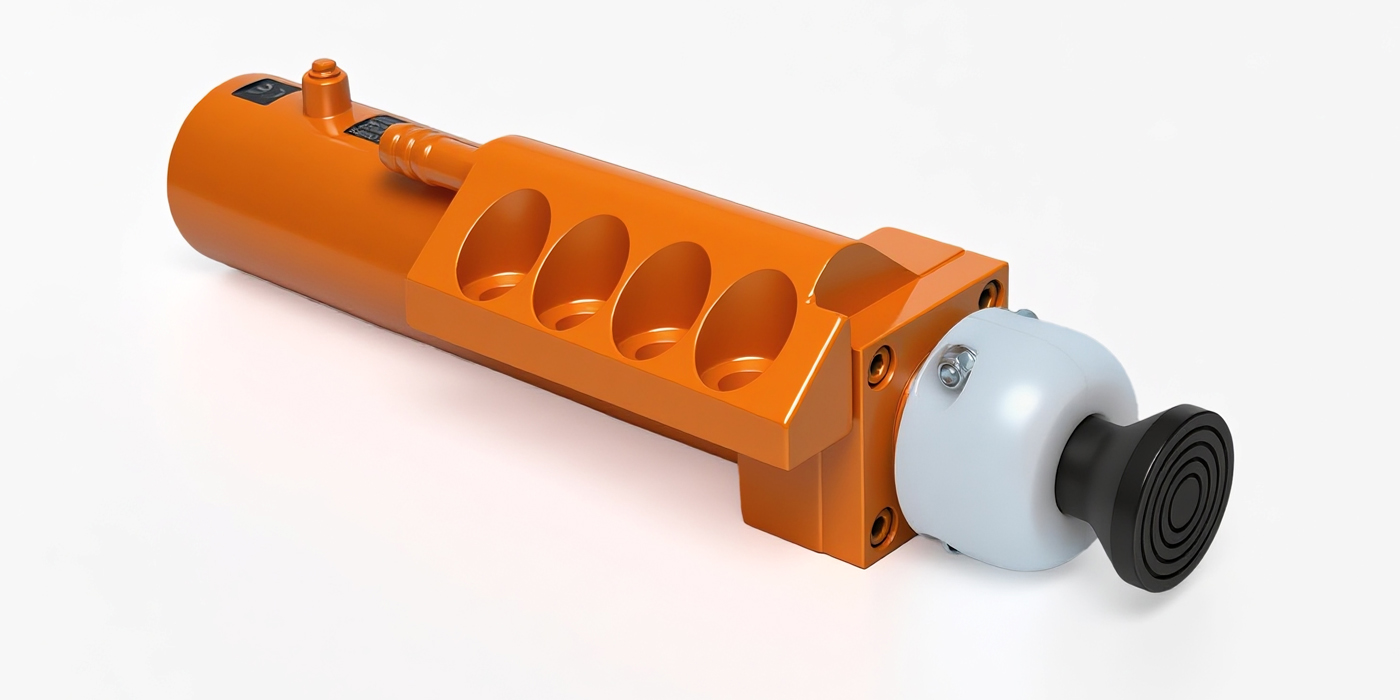

De-coring Hammer,

Decoring Machine

High technical performance. Compact and solid structure. Interchangeable with existing models in use on the market.

WHAT IS DECORING HAMMER?

More Energy Efficient and Efficient

DH series De-coring Hammer is a cost-effective pneumatic core removal tool.

Decoring work for cast aluminum alloy, cast steel, and other castings where internal sand core removal is difficult or sand core remains

- The vibration frequency is about 2-3%high(refer to the market with the same model)

- The vibration frequency is higher, the sand cleaning and core removal effect is better.

- Shorter vibrating cycle and efficient productivity

- Simple structure, high reliability, and long service life

- Provide spare parts replacement service for all parts of the Decoring hammer

- The DH series of Decoring hammers are identical in size to the same model of similar products in France and Italy and can be replaced entirely by interchange

- Personalized custom-made larger or smaller Decoring hammer that provides an increase or decrease

- The installation parts are freely customizable and the installation range is more flexible.

SAME SIZE AS SIMILAR PRODUCTS

IN FRANCE AND ITALY, EASY TO INSTALL

TYPES OF DECORING HAMMER

Higher frequency, clear sand, and de-coring are better

Depending on the customer’s request, we can offer Decoring hammer made of different performance parameters,in various grades of Vibration frequency, depending on the application.

Click here to download the product description

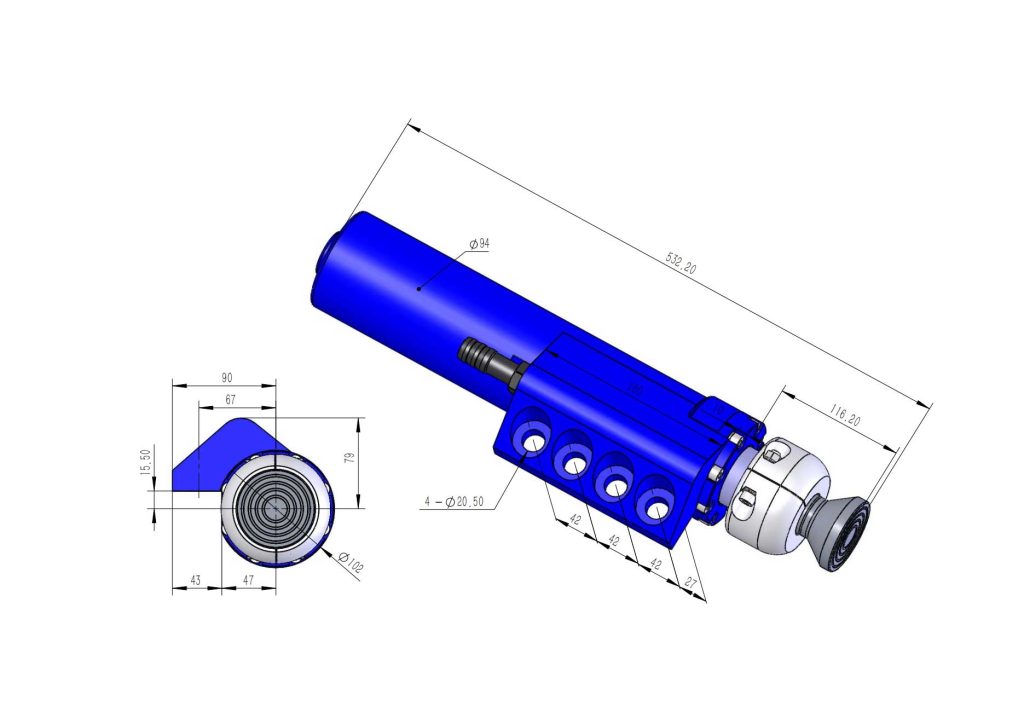

DH-19 Decoring Hammer

| Air pressure(Bar) | 4 | 5 | 6 |

| Frequency(Hz) | 19 | 19.5 | 21.1 |

| Hit times(c/min) | 1140 | 1170 | 1266 |

| Air consumption(L/min.) | 835 | 900 | 1035 |

| Air duct size | 3/4” | ||

| Recommended strike distance(mm) | ≤70 | ||

| Max strike distance(mm) | 120 | ||

| Weight(kg) | 23 | ||

DH-19 + Decoring Hammer

| Air pressure(Bar) | 4 | 5 | 6 |

| Frequency(Hz) | 19.5 | 21.1 | 22.1 |

| Hit times(c/min) | 1170 | 1266 | 1266 |

| Air consumption(L/min.) | 845 | 930 | 940 |

| Air duct size | 3/4” | ||

| Recommended strike distance(mm) | ≤70 | ||

| Max strike distance(mm) | 120 | ||

| Weight(kg) | 23 | ||

DH-21 Decoring Hammer

| Air pressure(Bar) | 4 | 5 | 6 |

| Frequency(Hz) | 21.1 | 23.6 | 25.7 |

| Hit times(c/min) | 1266 | 1416 | 1542 |

| Air consumption(L/min.) | 810 | 920 | 925 |

| Air duct size | 3/4” | ||

| Recommended strike distance(mm) | ≤70 | ||

| Max strike distance(mm) | 120 | ||

| Weight(kg) | 23 | ||

Notes:

- Recommended maximum air pressure 6bar

- Recommended to use the Mobil Aimeur 525 ISO VG 46 as the recommended lubricant

- Please be sure to clean when installing the pneumatic hammer. Remember not to bring dirt from the air hammer inlet into the hammer.

PRINCIPLE OF DECORING HAMMER

Design Science Environmental Protection and Energy Conservation

The compressed air is used as the power source, the air source switch is turned on, and the internal inner shaft tube assembly of the Decoring hammer is pushed out by the compressed air pressure until the front end hammer head presses the workpiece to be removed;

The switching of the position of the airflow reversing plug in the inner shaft tube assembly guides the airflow to make the piston rod perform periodic high-frequency reciprocating impact on the hammerhead, and the high-frequency impact force generated by the piston rod is transmitted to the workpiece through the hammer head and then transmitted to the sand inside the workpiece. The core separates the sand core, the sand core, and the workpiece, thereby efficiently removing the sand core.

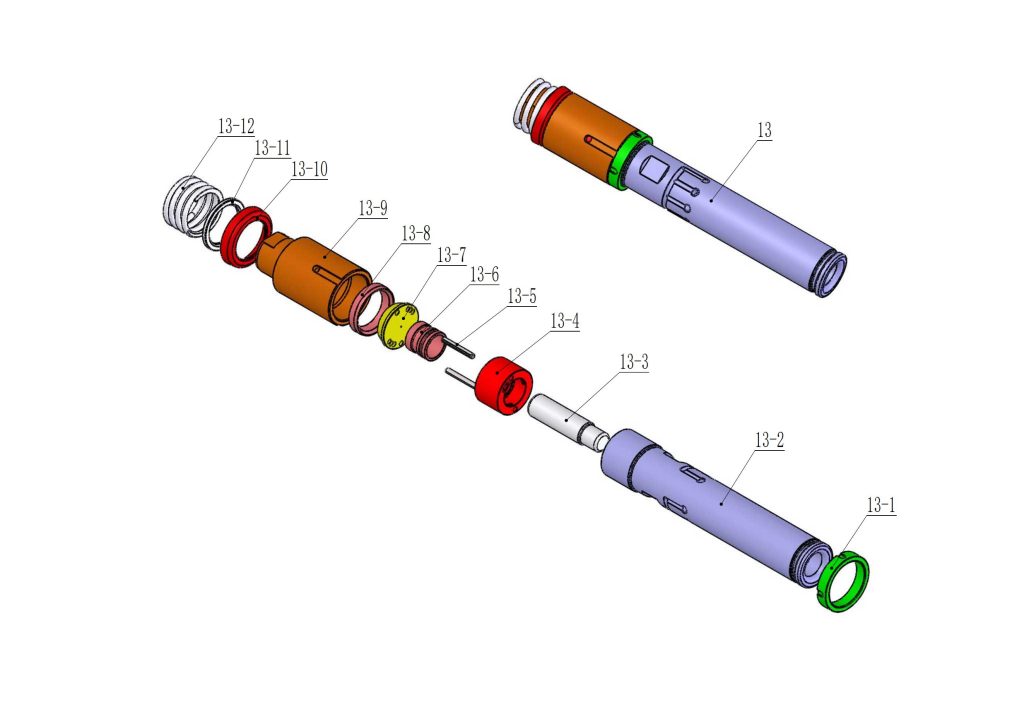

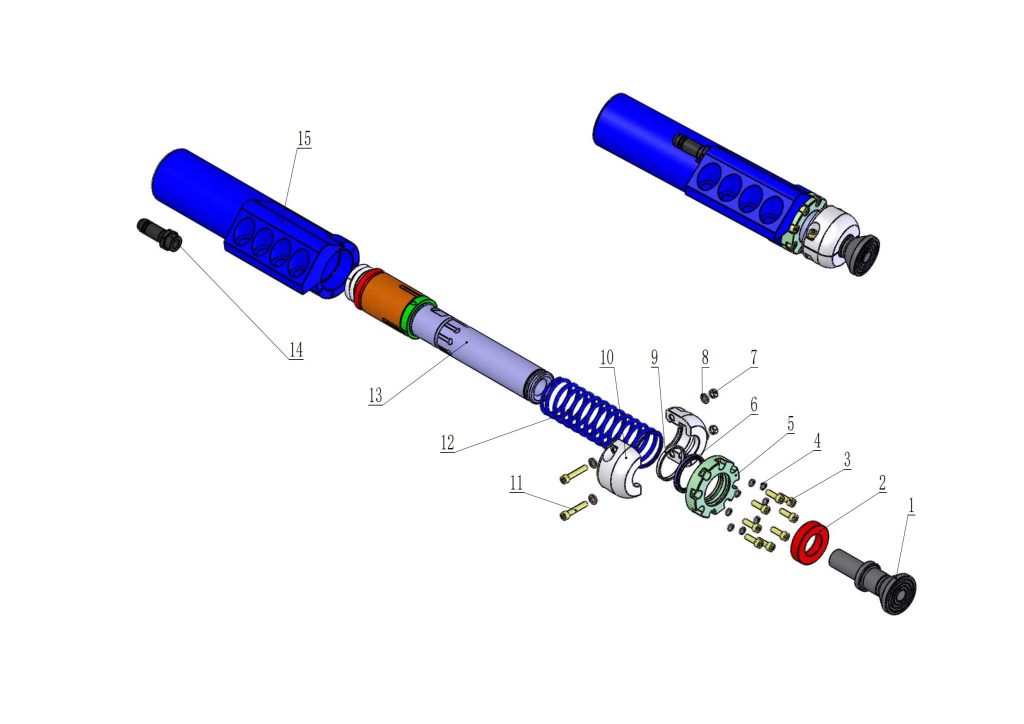

PARTS LIST OF DECORING HAMMER

Simple Structure and High Reliability

The decoring hammer must be lubricated regularly with lubricating oil.

We recommend lubrication with Mobil Amour 525 ISO VG 46. Each Decoring hammer needs to be lubricated separately(20-30 seconds for one cycle, one drop every 3-4 seconds).

If you have not used the Decoring hammer for a long time, you must use a degreaser to clean the inside.

After 510 hours of operation, Decoring hammer is recommended to inject the degreaser(recommended grade: Zep Dyna143)from the air inlet without removing the Decoring hammer from the core remover.

WARNING

- In order to ensure that multiple Decoring hammers on a single device can work properly, each Decoring hammer needs to use the same diameter and length of the pipeline.

- It is forbidden to use Decoring hammer without a hammer and casting!

- It is forbidden to use a pneumatic hammer without the workpiece that needs to be removed.

| No | Maintenance identifier | Name | Amount | Notes |

| 0 | PD Decoring hammer | 1 | ||

| 1 | ● | Hammerhead | 1 | |

| 2 | ● | Buffer washer | 1 | |

| 3 | – | Sealing screw | 8 | |

| 4 | – | Spring washer | 8 | |

| 5 | – | End cap | 1 | |

| 6 | # | Dust washer | 1 | |

| 7 | – | Machine Screw Nut | 2 | |

| 8 | – | Spring washer | 4 | |

| 9 | * | Support ring | 1 | |

| 10 | ● | Protective case | 1 | |

| 11 | – | Protective sleeve bolt | 2 | |

| 12 | / | Return spring | 1 | |

| 13 | * | Inner shaft tube part | 1 | |

| 13-1 | * | Inner shaft tube | 1 | |

| 13-2 | * | Piston rod | 1 | |

| 13-3 | * | Diversion sleeve | 1 | |

| 13-4 | * | Locating pin | 2 | |

| 13-5 | * | Airflow reversing plug | 1 | |

| 13-6 | * | Sealing cap | 1 | |

| 13-7 | # | Sealing cap washer | 1 | |

| 13-8 | * | Protective sleeve bolt seat | 1 | |

| 13-9 | * | Piston seal | 1 | |

| 13-10 | / | Buffer spring | 1 | |

| 14 | – | Exhaust port connector | 2 | |

| 15 | – | Double exhaust port | 1 | |

| 16 | – | Air inlet connector | 1 |

Precaution

When working for 300 hours or more, the Decoring hammer should be protected, inspected, and cleaned, and the degreaser injected from the inlet. You do not need to remove the Decoring hammer from the core remover.

Notes

- “ ●” The service life depends on the working environment conditions, such as the temperature of the struck casting.

- “ /” The Needs to be replaced after 1550 hours of hammering time, but if the distance between the hammer and the casting(ie the strike distance)is not within the specified distance, such parts need to be replaced after 1020 hours of hammering time.

- “ *” In order to prevent and maintain the Decoring hammer(after hammering for 510 hours or a little longer), these parts need to be repaired or replaced.

- “ #” These parts are recommended for replacement each time maintenance is performed.

SAFETY AND MAINTENANCE DECORING HAMMER

Provide spare parts replacement for all parts of the Decoring hammer

WARNING

- All parts must be our products. Using parts from other sources will reduce the safety of use and ensure the safety of Decoring hammer.

- The company is not responsible for products that do not use the original spare parts.

Maintenance

After the Decoring hammer is disintegrated, complete the following steps:

Check the condition of each part, clean them, or replace them. Reassemble the Decoring hammer step by step according to the reorganization steps. After reorganization, the Decoring hammer must be lubricated with Mobil Intermediate Lubricants.

Safety Guide

Follow the instructions for use.

When the Decoring hammer is not working properly,cut off the air supply.

When the noise of the Decoring hammer exceeds 85DB, measures to block noise(ear headphones,etc.)are required.

Air supply

To prevent damage, contamination, or rust in the Decoring hammer, use an air handling unit to ensure that the air supplied to the Decoring hammer is dry and clean.

The required accessories, lines, and pipes must be of appropriate size, consistent with the necessary air pressure, intake air volume, air output, and volume to avoid the pipe being too narrow(inappropriate use of the air pipe), resulting in insufficient air supply.

ABOUT US

Borisbang Industrial Technology (BIT) Co., Ltd.

Borisbang Industrial Technology is a casting equipment company that specializes in the design, manufacturing, and sales of foundry equipment.

BIT is dedicated to the design and manufacturing of de-coring hammers, de-coring stations, and decoring machines. Through continuous improvement and incorporating user feedback from the Chinese market, we work in collaboration with international experts to enhance the performance and lifespan of our de-coring equipment.

Our goal is to produce world-class products and provide global customers with cost-effective casting equipment.

With a comprehensive quality management system, strong technical expertise, and advanced production processes, we ensure the manufacturing excellence of our products. BIT’s highly skilled team of employees serves as a reliable guarantee for delivering exceptional services to our customers.

CUSTOMER

Customer:Daimler/BMW/Audi/VW/Ford

Customer:R.Scheuchl

Customer: Great Wall

Customer: Honda

Customer: Audi/BMW/BENZ

Customer: FAW

Customer: CRRC

Customer:Bosch/Vaillant

NEWS & EVENTS

Key Advantages of the Decoring Machine

In foundries, removing sand cores is a crucial process.Manual methods are slow, labor-intensive, and often damage castings.Today, decoring machines are transforming core removal with speed, precision, and automation.Below are five major advantages of…

Key Points For Safe Use Of Pneumatic Decoring Hammer

The pneumatic high-frequency vibration of the pneumatic decoring hammer is fast and high-frequency, will not damage the vibrating object, and can easily knock down the vibrated object. It has a long service life and is easy to install and maintain.

Four Major Features Of De-coring Hammerr for casting

The de-coring hammer has the advantages of pneumatic high-frequency vibration, fast speed, high frequency, easy installation and maintenance. The de-coring hammer is mainly used to remove the sand core inside the casting, including aluminum castings,…

Overview Of The Structure And Characteristics Of De-coring Hammer

Pneumatic decoring hammer is a device that uses pneumatic impact to vibrate and strike castings made of aluminum alloy and cast iron using core sand casting process, such as engine cylinder block, steel cover, exhaust pipe, pump body, valve body, pip…

Basic steps for maintaining and servicing the de-coring hammer

The pneumatic high-frequency vibration of the pneumatic de-coring hammer is fast and high-frequency, does not damage the vibrating object, and easily knocks down the vibrated object. The pneumatic de-coring hammer has a long service life and is easy …

Application Steps Of De-Coring Hammer In Foundry Workshop

In the foundry workshop, sand quaking and core removal is an important part of casting production. The de-coring hammer is a device that uses pneumatic impact to vibrate and strike castings made of aluminum alloy, gray iron, engine cylinder, steel co…